I found this review on Facebook ‘Machine Knitting’ group, and have to share it. I was so thrilled that this reviewer ‘got’ the book so thoroughly.

Book Review:

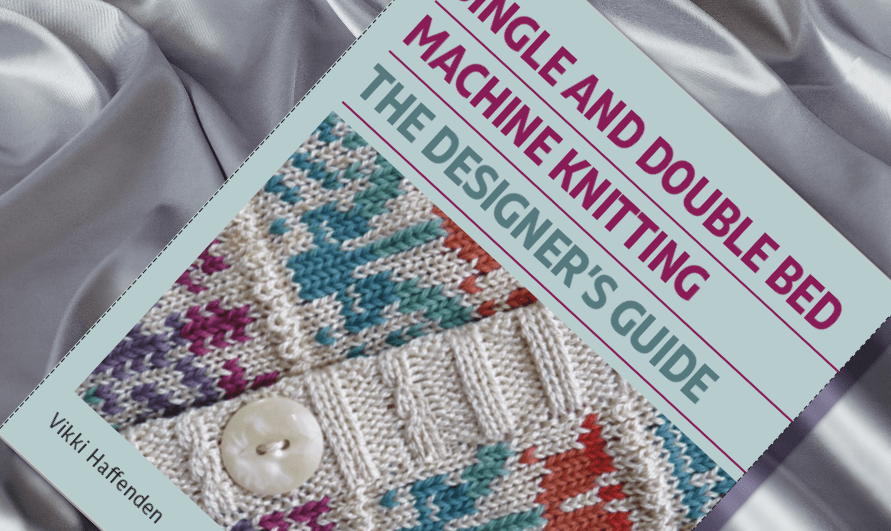

Translating Between Hand and Machine Knitting by Vikki Haffenden

☆☆☆☆☆☆☆☆☆☆ 10:10

“This book ought to be mandatory reading for every new machine knitter!” -me

“This book needs to be on every machine knitter’s manuals shelf, in pride of place, no matter if you use Silver Reed or Brother!” -me

“Where was this book when I was desperately trying to learn how to design lace/translate lace cards between Brother and Silver Reed?!?!” -me

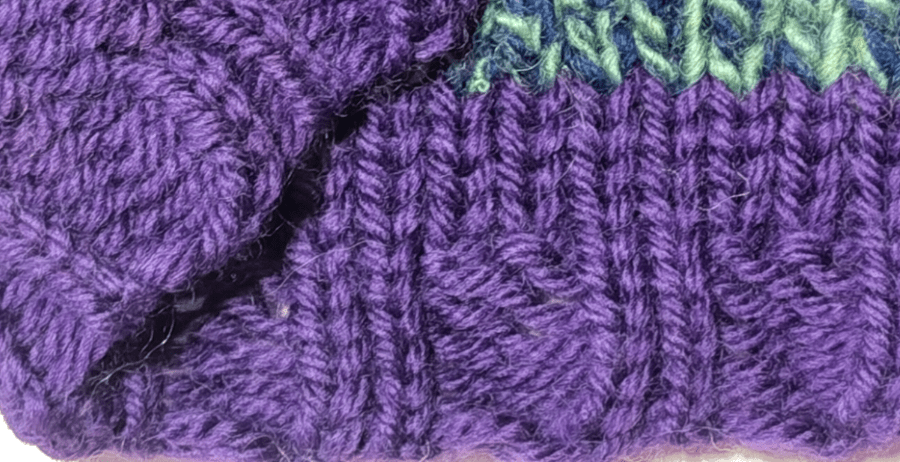

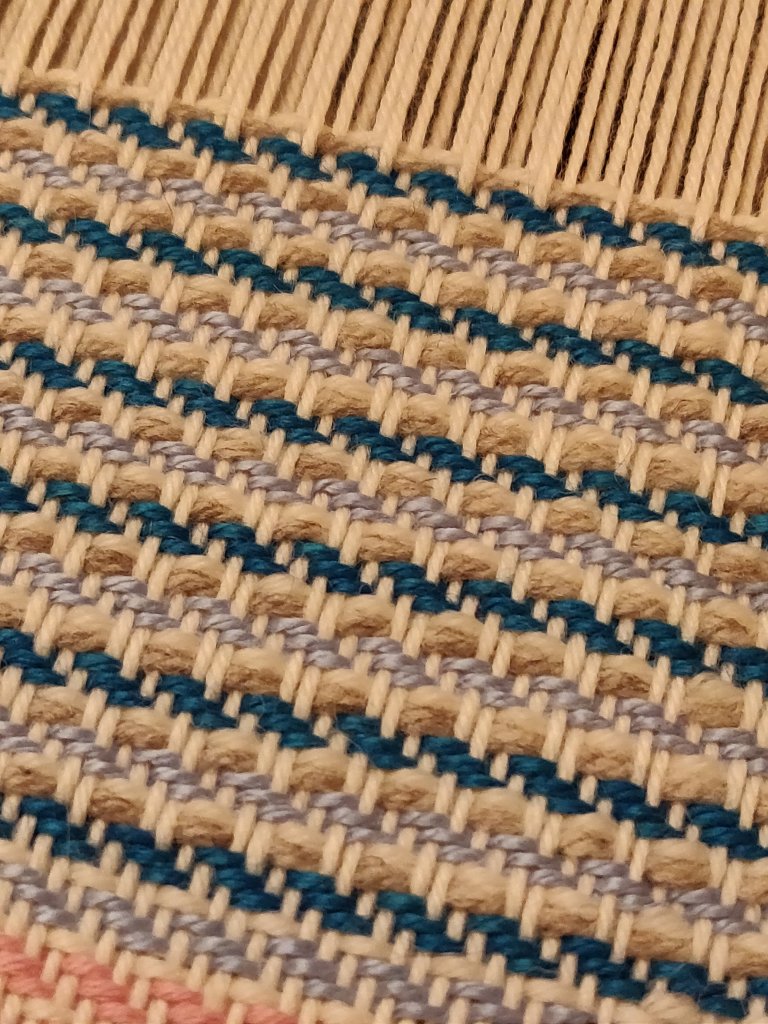

This book is absolutely essential equipment as far as I am concerned! It starts out covering and comparing materials and equipment for knitting, both hand and machine versions. The pictures will blow you away and they only get better. Please, at this point, re-read the title. It does not state ‘pattern’ in the title.

Next it goes into stitch construction and compares hand and machine and final product of each. This book give equal time to both! It goes into yarn fiber types, yarn construction(spinning), yarn types (boucle vrs worsted). The details are absolutely in depth and extremely easy to understand with stupendously clear focused pin-pointed and highlighted photography and exemplary diagrams that compare every aspect of stitches, fabric, mechanics, of hand and machine knitting. It breaks down differences between brands when there are differences, and does not favor either. There are some references to Toyota and Passap, but the main info concerns Silver Reed and Brother. This covers every type of cast-on and cast-off that I could remember!! It isn’t a how-to… it compares them and shows some GREAT visuals of them on and off the needles. Refer to your manual for specifics on how-to cast-on and cast-off. Basically, this book compiled most of the answers to questions I have asked in the past, questions I have hunted down answers to, and questions that I hadn’t even thought to ask. It is utterly fantastic. Only the very last chapter goes into translating PATTERNS between hand and machine…

Buy it! Buy it NOW!

I can not say enough how much you need this book! How much I needed this book… now if I can just convince her to write one on Passap…

No! I have no affiliation with the author… I wish I could say I know her.

Since reading it I have replied, so let’s hope we can converse about knitting I the future.