Having acquired a Devon/Cornwall fleece that is quite similar to a Romney in feel and quality, I thought I’d dye some for blending. This fine will be great to comb for a semi-worsted spun yarn.

One of my favourite methods for safely dyeing fleece without matting the fibres is to use a slow cooker. I have a large family sized one that will dye 100g comfortably and 150g at a pinch, and a single-person one that does 20g for samples etc.

Using a pre-mixed colour I’ve used before I did a blue first. However, on this fleece it came out darker than I anticipated, but will probably lighten up once combed or carded and spun.

From the remains of the dyebath I got a pretty light turquoise.

I have combed these colours as shown in this video.

I hoped.

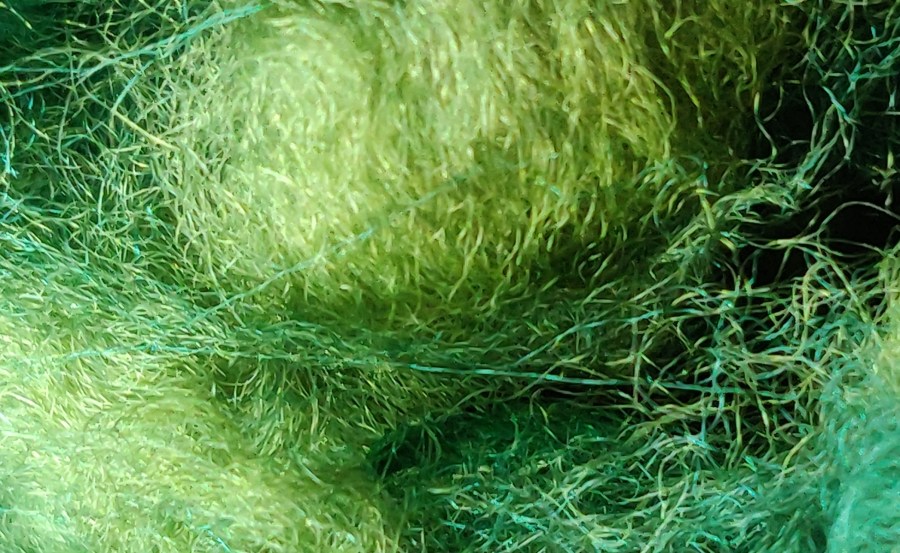

I also wanted an olive green, and have a recipe that worked perfectly on a Dorset fleece last year. I must have made a mistake somewhere, because I got a dark green instead. Maybe it is the different fleece, but I think I got my proportions wrong!

Once again they was some colour left in the bath, so in went 100g of Dorset fleece. OMG, the colour was bright! No idea what I did wrong, but it makes me blink.

That bright green total exhausted the dye – no surprise really! I will probably card this as the staples of the Dorset fleece are short and it is a soft fibre. Great for soft woollen spun yarn.

If you are interested in discovering the difference between different terms such as roving, tops etc, click here to read Abby Franquemont on Spin Off.