I have put some hand spun yarn in jar to Solar dye with raspberries. I am waiting for the outcome, but you can read more about the process by scrolling down the page here

The jar and contents working their magic…

I have put some hand spun yarn in jar to Solar dye with raspberries. I am waiting for the outcome, but you can read more about the process by scrolling down the page here

The jar and contents working their magic…

Cutting the warp off, is for me, a scarey, but exciting part of weaving. I started this inkle band during a workshop with the Somerset Guild of Spinners, Weavers and Dyers several months ago. When I got home I did a bit, but it sat part done in the corner for all this time until I was fired up to finish a few projects off and wove the last fifty or so centimetres yesterday evening.

This morning I cut the warp and will now wash the band. It is in 4ply hand knit/crochet cotton and follows a simple pattern that was set for the workshop. The colours were chosen to suit the living room curtains and if I ever get around to it I will make this band into tie-backs for the curtains, (which was my original intent).

It’s taken me a while, but I have finally made the warp which I will use for testing out my new (to me) countermarch loom.

It’s taken me a while as we have building work going on in the house so I am moving from room to room to escape the chaos. I finally ran out of places to go, so ended up in the conservatory which is HOT. Lots of short breaks needed.

I am in two minds about what to weave. My heart says a fleece rug – I have two in bags in the shed, but my mind says ‘ do you need a rug,?’ What I really need is more tea towels, since my son burned a hole in one of my hand woven ones.

The loom has got an 8 dent reed and I am using a thickish cotton and making a sectional warp because my warping board pegs won’t take more than 80 ends of this. I’ll thread it up as a twill and let myself be guided by the spirit of the day I start to weave.

The loom waiting for the warp. I know I’ll be whining about back ache quite soon…

Yesterday, a friend who I think has more spinning wheels than even I have, brought an older Louet wheel along to the monthly meeting of the Brighton Textile Arts Group. She didn’t know the model, and I still haven’t found it online, but that’s sort of irrelevant as it’s the Irish tension that caught my eye.

I have learned from many texts and posts online that ‘Scotch’ and ‘Irish’ don’t really relate to geographical origins. I also understand that ‘Scotch’ and double drive are both flyer-led and ‘Irish’ is bobbin-led (literal and more accurate descriptors), but the terms Scotch and Irish tension are in common use so I will stick to them here. In flyer led systems the wheel drives the flyer around the bobbin, and the bobbin is braked by either the brake band or the second loop of the double drive band. In bobbin led systems the bobbin is driven by the wheel so spins constantly, but the flyer, which feeds the yarn onto the bobbin is braked by either a leather band at the front (as on the Louet) or by using a brake band. In both systems, the spinner restrains the yarn from being pulled through the hooks/flyer and onto bobbin as twist is introduced in to the fibres and then releases their hold to allow the yarn to be drawn onto the bobbin. Both systems rely on some slippage of the bands, which is something I have not fully understood as yet, and am not sure is really necessary, but fascinating all the same. So far I am not sure how the difference in circumference of bobbin and flyer whorl affect each other in Irish tension as they do in double and Scotch tension systems. Another interesting thing to spend time testing out.

I learned to spin on a Westbury wheel, which was a gem of a wheel. My Mother bought it in Glastonbury as a kit – she was so excited, and my Dad built it for her and stained it dark walnut – not a fashionable option today, but it did look charming. The Westbury has both double drive and Scotch tensions, but I only used the Scotch option as we really didn’t understand the double drive. After this there was a gap in my spinning and Mum didn’t carry on with it for long, so that wheel has long gone, (something I really regret).

My interest in yarn design endured, but was industrially focused, so it was quite a few years later that I resumed hand spinning. I now prefer double drive but have several wheel which are switchable and value the flexibility this gives me. So that I can share with you, these are a Wee Peggy and a Schacht Matchless and an Ashford Traddie that I have converted to double drive but which still retains the option of Scotch tension. Of these the Matchless is a recent purchase, chosen after trying lots of wheels over longish periods of time, (hence my collection of wheels) and is my absolute favourite. It is a dream to spin on and has double treadles and a central orifice which is super ergonomic; I find single treadles can make me twist and lead to back and hip ache nowadays so can’t spin for too long on these.

So let’s get back to yesterday and the Louet wheel. Which is a sweetie I have to say. I like Louet wheels, (and of course own one) because they are so thoughtfully designed and this was no exception; sturdy with a central orifice and an onboard Lazy Kate, all made in lovely wood – very nice apart from the rather high treadle position. I’ve not used the Irish tension system before and so was keen to try it. I didn’t actually shove her out of the way, but hovered and green-eyed it and eventually asked if I could have a go. Generously she gave me fibre, and left me with it, saying she found it quite a challenge to be able to control what she was spinning, although I thought her samples were soft and pretty even. However, she was right!

After a while I managed to set the leather band so that the fibre wasn’t ripped from my fingers, and could start to spin. I found that very little tension was needed, which I am not sure is normal. We inspected the tension band, orifice and brass bearing and whilst the band didn’t look worn at all, the orifice outer was a bit sticky and the brass bearing seemed a bit rough. We cleaned these as best we could with what we had to hand which helped a little, but probably a gentle swab of alcohol on the orifice outer and brass would be a good idea.

Once it was going I was really surprised how different the Irish tension felt to the two other systems, and can see why it is good for thicker yarns because of its pretty intense pull-in. Plus I imagine it is great for plying. However I managed a reasonably even singles that was indeed thicker than I usually spin double drive, so that sort of proved it to me.

Being an equipment squirrel I immediately wanted an Irish tension wheel. So imagine my joy when I found that my Matchless would convert to Irish tension! In my excitement of first owning the Matchless I tried both double and Scotch tensions and have been using these both since then, but I clearly forgot that it has three tension modes. I’m not sure it tells you in the manual, but you simply swap the drive bands over. The wheel drive band goes on the bobbin, and the Scotch brake band on the flyer whorl. I have set mine with the larger bobbin whorl to the back with the medium flyer whorl, there may be better arrangements but I have yet to try these out.

The result felt very similar to the Louet, with the brake band needing hardly any tension, so maybe that is normal after all. I found starting needed care so that the fibre doesn’t pull away too rapidly, but once going it went well. It might be me, but most times after I moved hooks the pull-in became stronger, then settled down again. This must be because the smaller circumference of the bobbin to start with pulls the yarn in faster. Because of this I can see why a Woollee Winder type system might be useful with this tension system, but I am not tempted due to price. The hooks will do me just fine and I really don’t like the sliding hooks on any make so far.

As you will see in the photos, the singles I spun are nothing to write home about, but its early days for the Irish tension set-up. The fibre is onion-skin dyed Lleyn blended, (rather poorly because I was in a hurry) with rust coloured Alpaca, then taken as tops off the drum-carder.

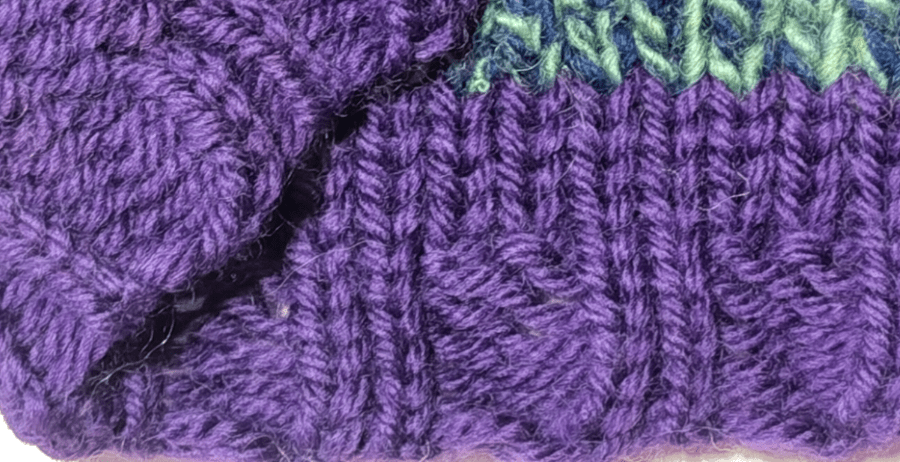

Reformin, or ‘latching-up’ single bed stitches into a rib structure is sometimes seen as far too time-consuming for a ‘fast’ activity like machine knitting. However, I quite enjoy the process and have written about it and made a ‘workshop’ video of working a 2×2 reformed rib here. I hope you find it of interest and useful.

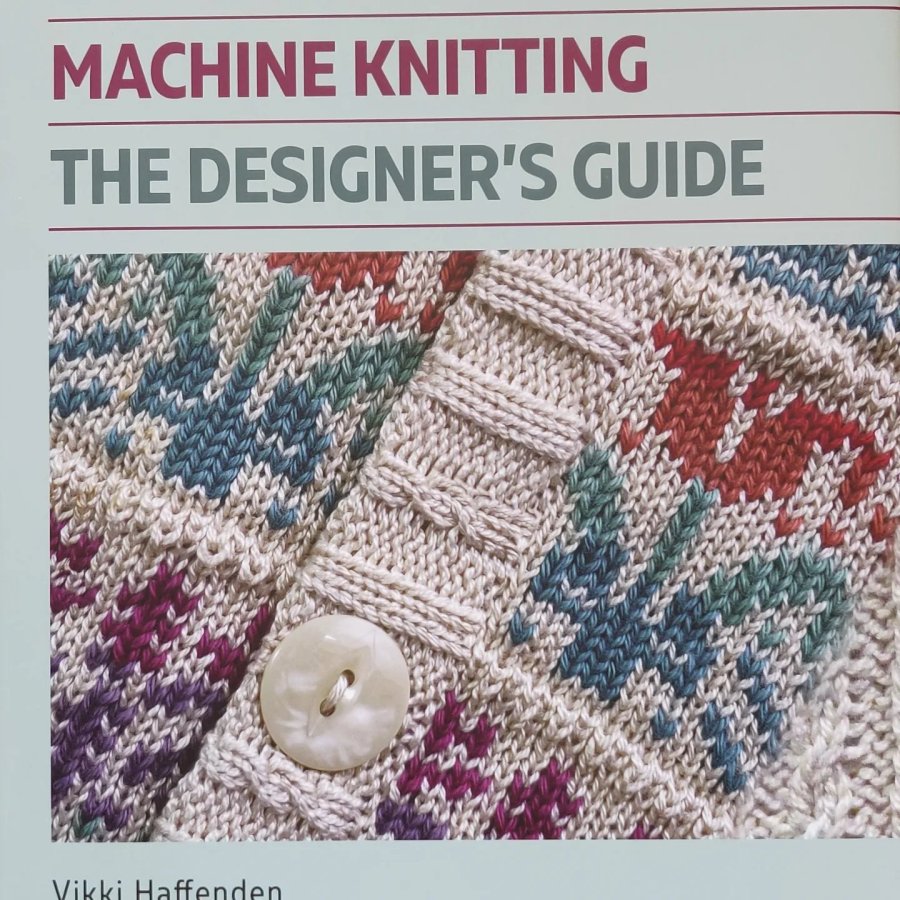

November’s edition of Machine Knitting Monthly has a great review of ‘Single and Double Bed Machine Knitting; the Designer’s Guide’. Amongst other nice things, they mention the broad scope of the book’s contents. I deliberately wrote so that it is suitable for any machine owner from Brother to Passap with lots of hints and tips to work on different types of machines. Thank you Machine Knitting Monthly!

Read excerpts from the review here.

I found this review on Facebook ‘Machine Knitting’ group, and have to share it. I was so thrilled that this reviewer ‘got’ the book so thoroughly.

Book Review:

Translating Between Hand and Machine Knitting by Vikki Haffenden

☆☆☆☆☆☆☆☆☆☆ 10:10

“This book ought to be mandatory reading for every new machine knitter!” -me

“This book needs to be on every machine knitter’s manuals shelf, in pride of place, no matter if you use Silver Reed or Brother!” -me

“Where was this book when I was desperately trying to learn how to design lace/translate lace cards between Brother and Silver Reed?!?!” -me

This book is absolutely essential equipment as far as I am concerned! It starts out covering and comparing materials and equipment for knitting, both hand and machine versions. The pictures will blow you away and they only get better. Please, at this point, re-read the title. It does not state ‘pattern’ in the title.

Next it goes into stitch construction and compares hand and machine and final product of each. This book give equal time to both! It goes into yarn fiber types, yarn construction(spinning), yarn types (boucle vrs worsted). The details are absolutely in depth and extremely easy to understand with stupendously clear focused pin-pointed and highlighted photography and exemplary diagrams that compare every aspect of stitches, fabric, mechanics, of hand and machine knitting. It breaks down differences between brands when there are differences, and does not favor either. There are some references to Toyota and Passap, but the main info concerns Silver Reed and Brother. This covers every type of cast-on and cast-off that I could remember!! It isn’t a how-to… it compares them and shows some GREAT visuals of them on and off the needles. Refer to your manual for specifics on how-to cast-on and cast-off. Basically, this book compiled most of the answers to questions I have asked in the past, questions I have hunted down answers to, and questions that I hadn’t even thought to ask. It is utterly fantastic. Only the very last chapter goes into translating PATTERNS between hand and machine…

Buy it! Buy it NOW!

I can not say enough how much you need this book! How much I needed this book… now if I can just convince her to write one on Passap…

No! I have no affiliation with the author… I wish I could say I know her.

Since reading it I have replied, so let’s hope we can converse about knitting I the future.

I have just bought a Louet W70 loom to expand my skills. It is a 4 shaft and has a stand. From my internet searches I understand this look to be the earliest version of the Louet Kombo Loom, that then became the Jane. It’s very sturdy and U think I am going to have fun with it!

I mentioned that it would be great if I could pedal the shafts. My son took one look at it and was determined to add those pedals!

Today we spent a lot of time trawling the internet for old instruction manuals and seeing what other people had done when converting table looks to treadle ones. There is one video on Facebook that we found very informative, and so we started. He has so far designed a direct tie-up method for lifting the shafts and is now working on designing the treadles. Meanwhile I have ordered Texsolv cord and clips to make the tie-up easier and so that the pedals can be disconnected to enable folding the loom away.

Update

The loom is now working. It has four direct threaded treadles and I’m working on it with a short, narrow test warp using some wool/acrylic and a 10epi reed.

The advance copy of my new book arrived today, and you can see some pages from the book here.

Meanwhile here is a quick look at the book.

I have made a more in depth video introduction to the book, and if you would like to watch this, please keep on scrolling down the page.

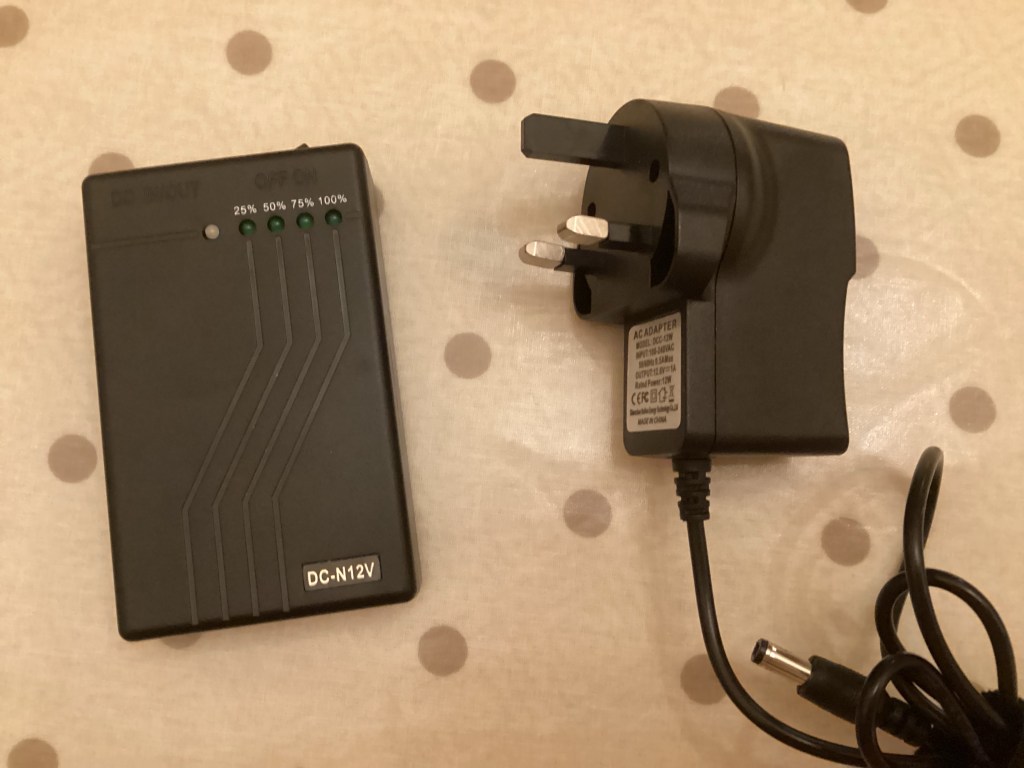

I’ve just spent about an hour fiddling with the battery pack that came with my E-Spinner. The E-spinner was secondhand and was still unassembled and the battery never been used – the battery pack is not an Ashford one. I thought the details of the battery pack might be useful for anyone looking to buy one of these for their E-Spinner 3.

Super Rechargeable Li-ion Battery, YSN-N12V

Input: 12.5VDC

Output: 12VDC 3800mAh, (this is the DCin/out outlet, a round plug that leads to the E SPinner power plug when being run on battery).

Other output is: 5VDC 6800mAh – (the usb outlet).

In my excitement I charged it rather haphazardly, but it has been working fine with the spinner. When I came to recharge it I found that it was not indicating charging as explained in the manual. However, a useful review on YouTube enabled me to understand what was going on. There is another lead with the battery, a round pin on one end (that is the same size as the outlet, and a much thinner pin on the other end – no idea what that is for). The lead from the battery to the E-spinner has the same sized pin on each end. It may have been purchased separately from the battery pack?

Basically the instructions were confusing about the charging process. The led on the plug the goes into the wall outlet is supposed to be red when the unit is plugged in to charge, and turn green when it is charged. The unit also must be switched on at its own on/off switch whilst charging, (if you leave it switched on when not in use it will discharge). The battery pack has five green lights on the top, one to show the pack is charged and four others labelled 100%, 75%, 50% and 25%. Nothing is said in the instructions about these, but trial and error showed that pressing the unlabelled button on the left side of the unit indicates the amount of power remaining in the unit using these lights.

I couldn’t find the battery pack on eBay or Amazon but did find it on AliExpress.

I found the same battery pack on aliexpress

I have used the battery for about 4-5 hours spinning before it needs recharging, so am really pleased with the unit. I have also bought the cigarette lighter plug connection so that I can use it on the 12v in our caravan. May be overkill as the battery is working well so far. The battery takes about 8 hours to charge.

Updated September 2025

Having been browsing I have found several posts about the battery for the E Spinner 3. Because mine does run out sometimes, I decided to purchase a second one and found this TalentCell one recommended on FB at a reasonable price so have taken the plunge.

Here is a link to the post on the Spinning Fibres group about the battery, which includes how to trim the plastic on the plug if it is too big for hole on the E- Spinner.

The details of the battery are : TalentCell Rechargeable 12V 6000mAh/5V 12000mAh DC Output Lithium ion Battery Pack – Portable Li-ion Power Bank with 12.6V Charger, Black.

I can give no guarantees that it will work, and have no affiliation to any of the companies named here.

I will post again if this does not work…